Slurry is prepared by mixing appropriate ratio of anode or cathode materials with binder conductive materials under vacuum for a specified period of time

| R & D Line Range | 5 ~ 15 Ltr |

|---|---|

| Pilot Scale | 50~100 Liter |

| Mass Scale | 500~1000 Liter |

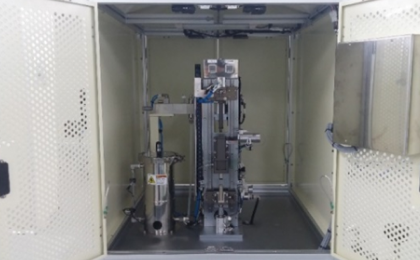

The foil is coated with the slurry using an application tool The foil is coated either continuously or intermittently in the coating direction. Generally, the top and bottom sides of the foil are coated sequentially.

| Coating width | 50~700mm |

|---|---|

| Line speed | 1~10 m/min |

| Coating type | Slot die, Comma Reverse Coating |

| Mode | Continuous, intermittent & Multi stripe |

| Line Support | R&D , Pilot Scale & Mass Production Line |

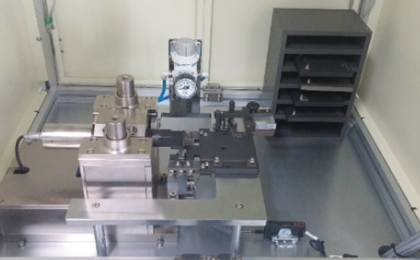

Roller press calendar compresses and compacts the coated electrode onto the current collector metal foils to improve the energy density of the battery, provide even thickness and density.

| Line speed | 1~10 m/min |

|---|---|

| Foil Width | Max. 700mm |

| Pre heating | Electric Heater(Max.150°C) |

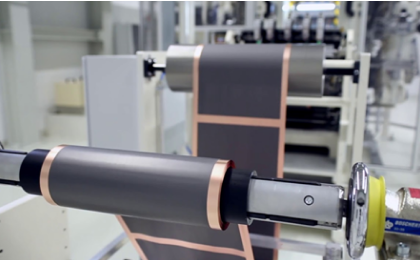

The slitting machine can slit electrode with width up to 500mm, and with finished slitting width from 20mm to 500mm with different model cutter blade.

| Line speed | 1~30 m/min |

|---|---|

| Slitting type | Shear Knife Type |

| Knife cutting | Max. 7 Cut |

| Slitting width | Min. 40mm |