Aluminum foil is the only material suited for lithium-ion battery cathode current collectors.

The Aluminum foils have excellent performance in lithium-ion cell manufacturing. Al is generally used for high-energy, high-power applications. Al foil is extensively used in consumer electronics and electric power tools. It is also widely used in Hybrid and Electric vehicle (EV) battery applications.

| Thickness | 10~20 microns |

|---|---|

| Width | 100~300 mm |

| Length | To be determined |

| MOQ | 10kg |

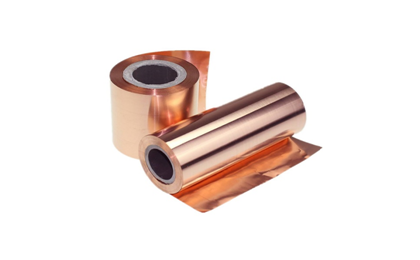

Copper Foil is used as the negative electrode for the anode current collector.

High-performance copper foil materials has been developed to meet the specific needs of the lithium-ion battery manufacturing industry.

| Thickness | 10~20 microns |

|---|---|

| Width | 100~300 mm |

| Length | To be determined |

| MOQ | 10kg |

Electrolyte plays a key role in transporting the positive lithium ions between the cathode and anode. The most commonly used electrolyte is comprised of lithium salt, such as LiPF6 in an organic solution.

| EC:DEC:EMC (1:1:1), 1 M LiPF6 |

| EC:DEC:DMC (1:1:1), 1 M LiPF6. |

| EC:PC:DMC (1:1:3 + VC 2%),1 M LiPF6. |

Separators can be made from a variety of materials, including cotton, nylon, polyester, cardboard, and synthetic polymer films. Separators do not chemically react with either the anode, cathode, or electrolyte.