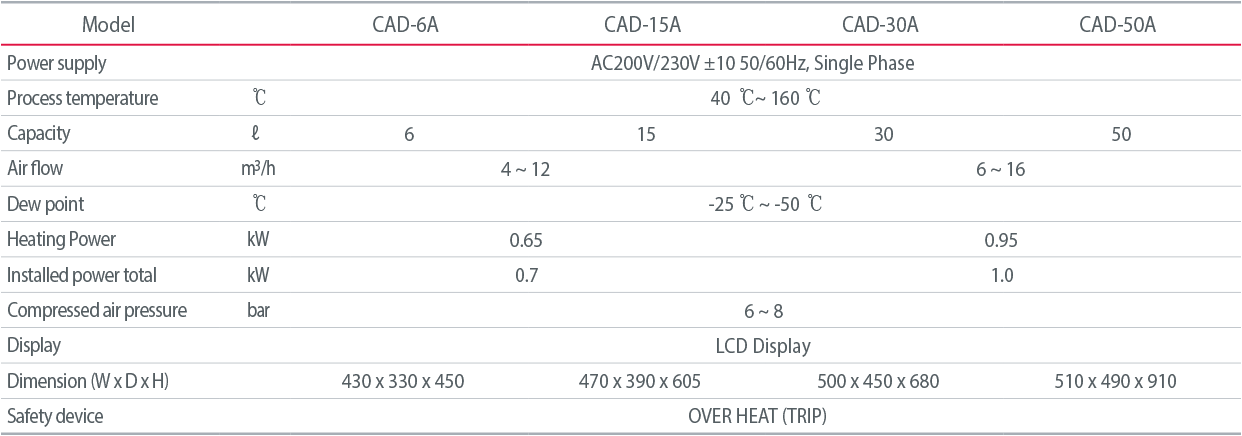

Optimized for high precise plastic injection molding such as mobile phones,optical lenses,light guide plates.

Consistent drying and Energy saving by controlling air flow of each hopper acoording to material and its quantity

Innovative Energy-saving effect with Hot Air Recycling function

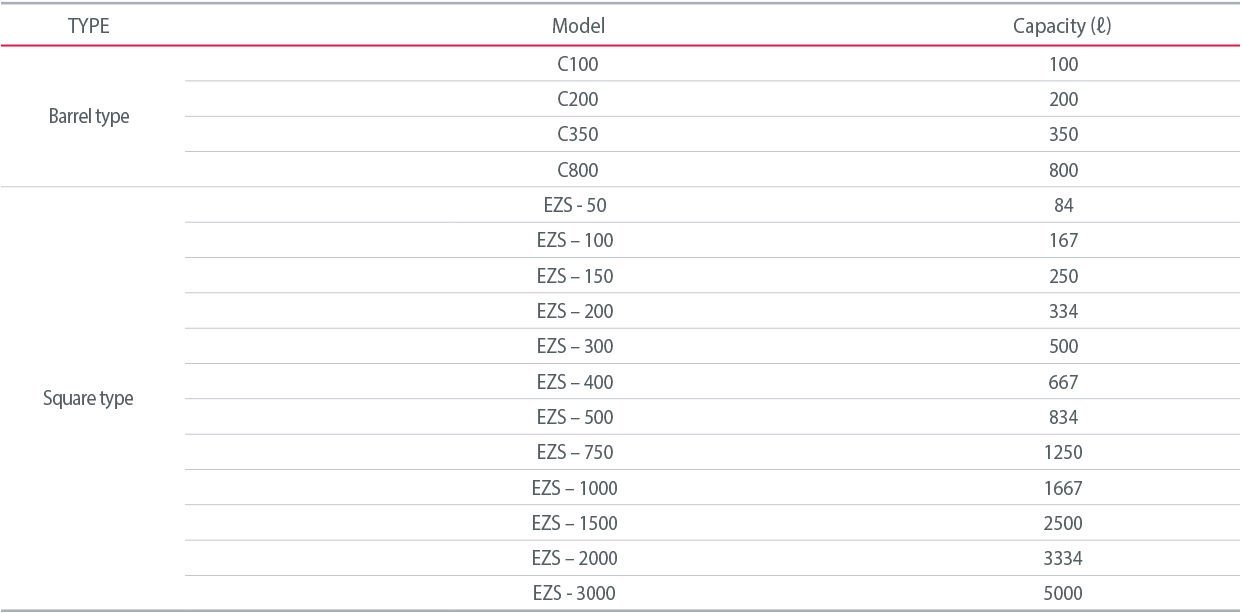

EZS series is designed for optimum performance including durability and prevention of material's contamination in injection molding process,which a large amout of materials is needed.

FOS-2000 is designed to be operated at water supply temperatures from 10℃ to 120℃ and only for water. The high head-capacity and high flow rate features enable the customers to select even the large size injection molding process.

The multi zone type, separately controlling the temperatures of the core part and the cavity part is also available.

Checking shortage of material and supplying material connecting hopper loader

Smooth material supply by using various receivers

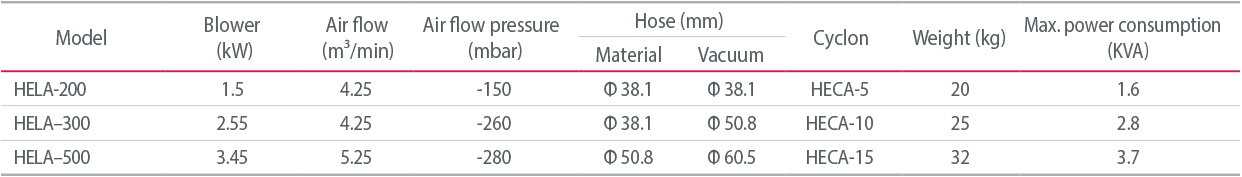

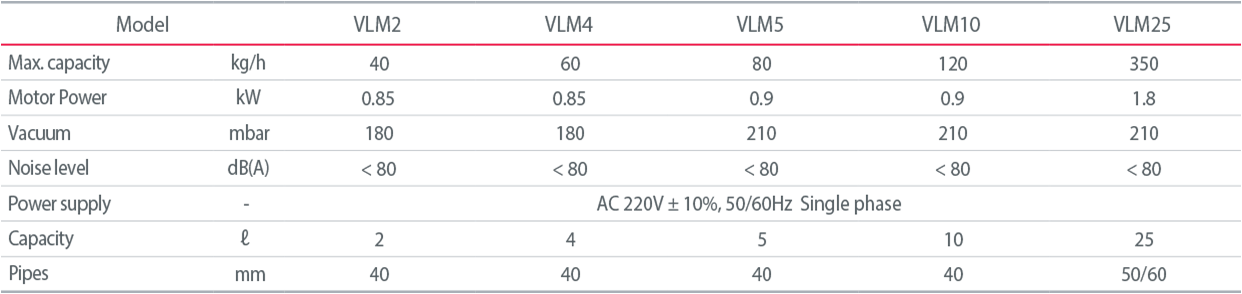

Single loader VLM series consist of second stage blower,big filter,auto filter cleaning and removable tissue filter and gasket.

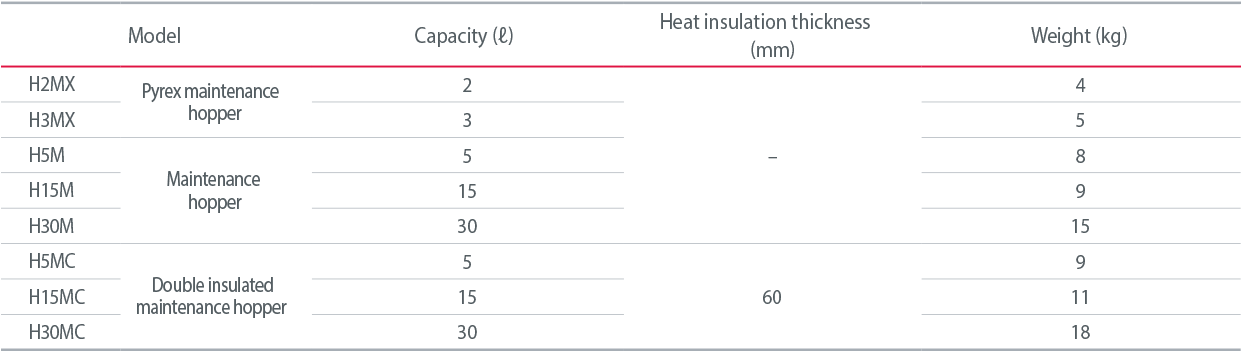

Insulated models enable to maintain an even temperature of the material when it stays on the machine for a long time.In case of small throughput a pyrex base is available to visualize material before it gets into the auger.

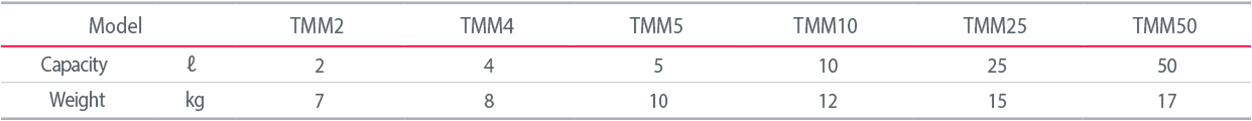

TMM series are specially designed for centralized auto feeding system