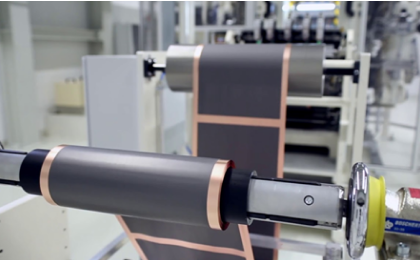

Roller press calendar compresses and compacts the coated electrode onto the current collector metal foils to improve the energy density of the battery, provide even thickness and density.

| Line speed | 1~10 m/min |

|---|---|

| Foil Width | Max. 700mm |

| Pre heating | Electric Heater(Max.150°C) |

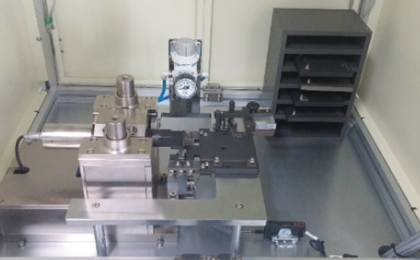

The slitting machine can slit electrode with width up to 500mm, and with finished slitting width from 20mm to 500mm with different model cutter blade.

| Line speed | 1~30 m/min |

|---|---|

| Slitting type | Shear Knife Type |

| Knife cutting | Max. 7 Cut |

| Slitting width | Min. 40mm |